How To Troubleshoot Surging Lawn Mower Engines

Lawn mower surging results from continual accelerating and decelerating of engine revolutions. The sound resembles repeatedly throttling up and powering down the mower. The mower may not die completely as this happens, but it may surge the entire time you mow the lawn. Knowing that an improper balance of fuel and air causes surging helps develop your troubleshooting plan.

Clogged Air Filter

Paper air filters that are so dirty you cannot easily see light through them starve the engine of air. Replace this type of filter with one designed for your mower. Foam air filters may not pass the light test even when clean, since they are denser. Clean foam filters with soapy water, dry them completely, and then give them a light coating of engine oil before returning them to the air filter tray. With either filter, wipe any dirt out of the filter tray before installing.

Fuel System Troubles

Proper fuel delivery depends on some backpressure from the fuel tank. That pressure comes from a tiny hole in the gas cap. If it is sealed shut with dirt, the carburetor cannot get enough fuel. Remove the cap and clean it with a paper clip or needle. Water in the fuel is another issue that causes surging. Water can enter the gasoline through condensation, rain or from the fuel station. A fresh batch of fuel should solve the problem. Always dispose of discarded fuel properly. Contact your local environmental agency for instructions on getting rid of old fuel.

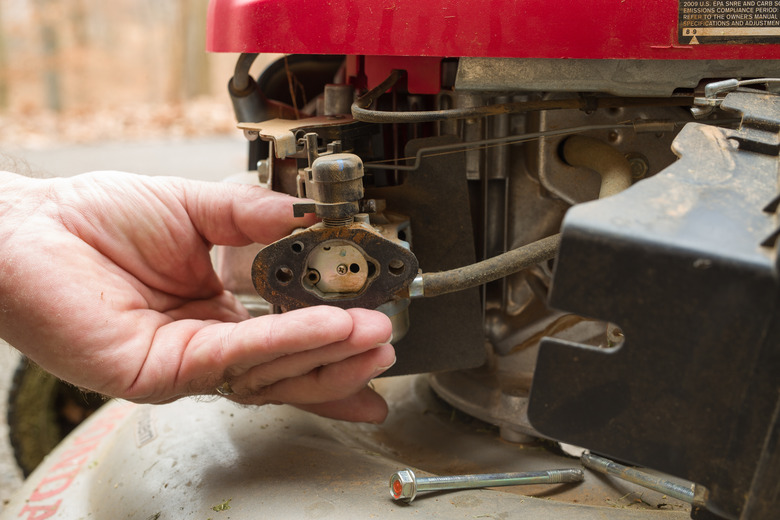

A Fouled Carburetor

Carburetors can also get fouled by dirt and grime that gums up its internal components. You can take your mower to a small engine specialist or remove just the carburetor and take it in for cleaning. If you are comfortable in your machine repair skills, you can disassemble and clean the carburetor yourself. Check the float for pinholes and free movement, and clean the orifices, ports and needle valves with carburetor cleaner approved for your engine. Use a carburetor kit if you find any damaged components or torn gaskets. Replace a carburetor that is in bad condition or has a damaged body.

Vacuum or Air Leaks

If the carburetor's hold-down bolts loosen or if the gasket that mounts between the carburetor and the engine block develops cracks, excess air flows into the fuel mixture. The air imbalance also compromises the vacuum needed to move fuel, air and the fuel and air mixture through the carburetor. Check the gasket, tighten the bolts and inspect the air-intake manifold for leaks. Tighten bolts or replace worn parts as needed to correct any problems that arise during troubleshooting.